How K2 became the first ski company to roll out an entirely rockered line…

We’re standing inside a freezer the size of a massive walk-in closet. I’m with Jeff Mechura, K2’s VP of global marketing, at K2 headquarters in Seattle, Wash. I forgot my down jacket and my breath appears frosty in front of my face. Mechura won’t stop talking about the machine cranking back and forth nearby that’s trying, repetitively, to break a pair of skis.

“Usually when I’m on a tour like this, I like to just take my time. Just talk. Until someone says, ‘I’ve got to get out.'” Mechura jokes. “I’m totally at home in here.”

I came here to talk about the fact that K2’s entire ski line for 2010-2011 — from the beginner-friendly groomer skis to the powder skis — has rocker in it, the first time K2 has released a 100 percent rockered line. But somehow, I’m stuck in this freezer.

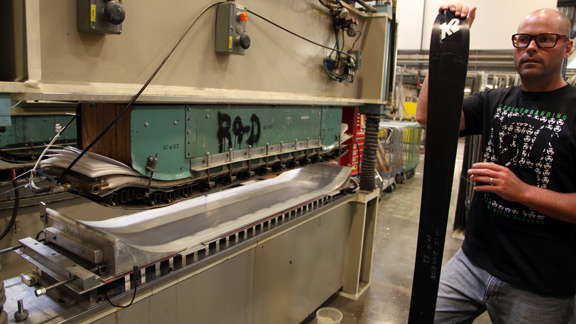

After a few frigid minutes, he opens the door leading out to the rest of the factory, where they produce K2 prototypes (all of the production samples are made overseas). He walks me through the process of how a ski is made: bases, edges, core materials, molding, graphics. He tells me that there are certain machines that I can’t take a picture of, specific operations that K2 would like to keep private. He tells me that Seth Morrison was at the factory in June, tweaking the design of his pro model. He shows me the office skate ramp.

Then he leads me into the marketing department, where there’s a bar decorated with ski paraphernalia. Then finally, we sit down, and I get to ask him about K2’s entirely rockered line.

“What we learned is that a fully rockered ski is great, but it’s got only one application: powder,” Mechura says. “But as we tested skis even more and started to noodle around with them, we found that rocker had a ton of different applications to it. It’s really the combination of rocker and camber that makes a great ski. So that’s how we came up with this idea of Baseline technology.”

Baseline is K2’s trademarked term that offers a sliding scale for how much camber and rocker a ski has, and as a result, what type of terrain that ski is meant for. It includes Powder Rocker, Jib Rocker, Speed Rocker (for hard snow), Catch Free Rocker (for beginners) and others.

K2 isn’t the only company using rocker in skis made for something other than just deep powder. Salomon, Atomic, Head, Rossignol, Dynastar and others all have incorporated rocker into their all-mountain skis. But K2 is the first major ski company to adopt rocker in every single one of its skis. (On the snowboarding side, Lib Tech was the first to bring rocker to its full line for snowboarding in 2008.)

“To say that our model line is 100 percent rocker this year, well, yes that’s accurate. But you could also say that it’s 100 percent camber,” Mechura says. “While rocker is a super buzzword right now, it’s not just rocker that’s making skis better these days. It’s the blending of camber and rocker.”

He explains that they didn’t intend for every ski to have rocker this year — it just sort of happened that way. And naturally, he credits a lot of K2’s design ideas to their athletes, namely the late Shane McConkey, but also pro riders like Seth Morrison, Pep Fujas, Sean Pettit, Andy Mahre and the Crist brothers, who give detailed feedback on samples they test in the field.

Mechura has been working at K2 for 14 years now — first as a team manager, then as a product manager and now as head of marketing — and he admits that this is a big year for the company, the year they bring rockered technology, or “Baseline” as he keeps insisting, to the masses. “This is the first year that this has been the case,” he says. “No question that this is a benchmark year.”